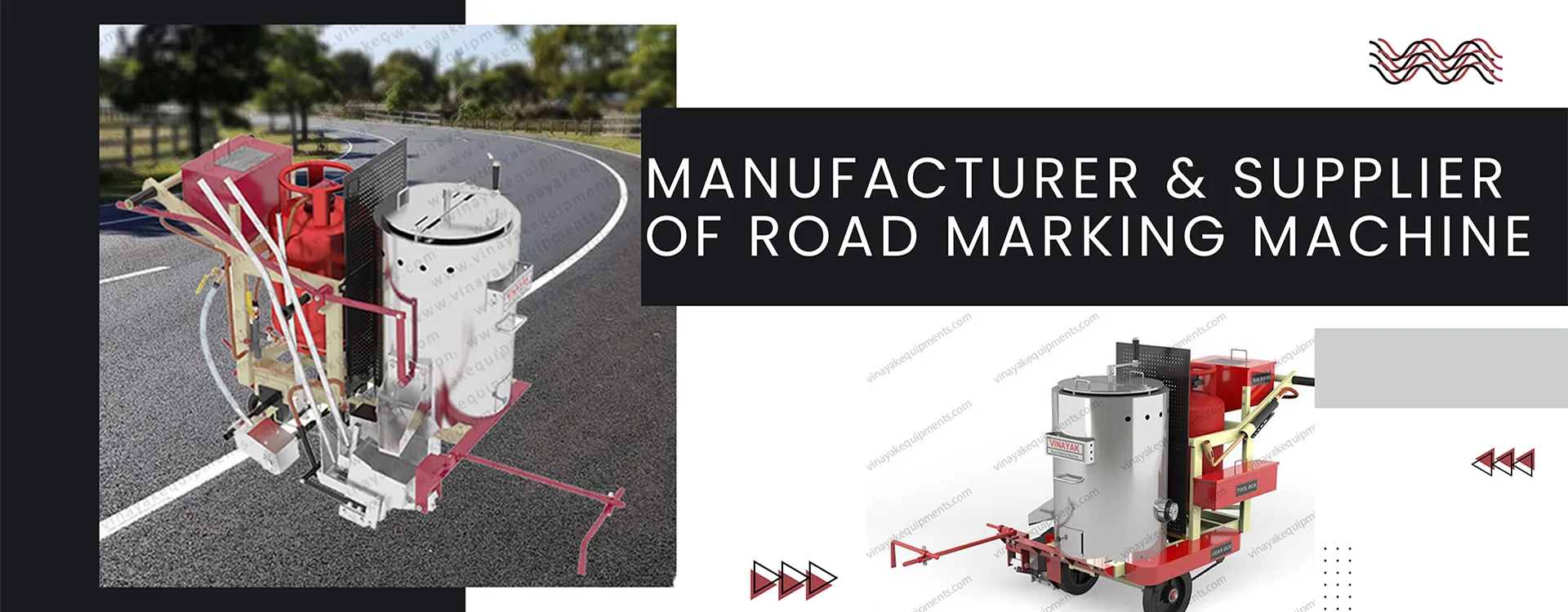

By adding visible lines, symbols, and signs to road surfaces to direct and control traffic, road marking devices are vital to maintaining road safety. Renowned road construction equipment maker Vinayak Equipment provides high-performance road marking machine that are built for precision, effectiveness, and endurance. The exact application of marking materials, such as cold paint or thermoplastic paint, is the core of these devices' operation. The paint mixture, which consists of pigments, glass beads, and binders, is heated to a high temperature (usually between 180°C and 200°C) in an integrated preheater in thermoplastic material road marking systems.

The idea behind road marking machines is to apply marking materials to road surfaces precisely and carefully in order to improve safety and communicate traffic laws. To guarantee excellent performance, efficiency, and dependability, Vinayak Equipment, a top Road Marking Machine Supplier sector, bases the design of its road marking machines on cutting-edge thermal and mechanical principles. The fundamental idea is the application of either cold paint or thermoplastic. In thermoplastic systems, the road marking machine manufacturer is first heated in a thermostatically controlled preheater to a predetermined temperature, usually between 180°C and 200°C. After that, the molten material is pushed to an extrusion head or marking shoe, where it is laid down in the required line pattern.

| Feature | Specification |

|---|---|

| Machine Types | Thermoplastic / Cold Paint / Hybrid |

| Drive System | Manual Push / Self-Propelled / Vehicle-Mounted |

| Marking Speed | Up to 5 km/h (surface & marking dependent) |

| Line Width Range | 50 mm to 300 mm (adjustable) |

| Line Thickness | 1.5 mm to 3 mm (application dependent) |

| Surface Compatibility | Asphalt, Concrete, Paver Blocks |

| Heating System | LPG or Diesel Burner (for thermoplastic systems) |

| Paint Application | Extrusion / Screed / High-Pressure Airless Spray |

| Glass Bead Dispenser | Manual / Automatic (Gravity or Pressure-fed) |

| Control System | Manual, Hydraulic, or Pneumatic (based on model) |

| Tank & Build Material | Stainless Steel or MS with Anti-Corrosive Coating |

| Optional Features | Digital Temperature Control, Bead Spray Timer, Reflective Tape Applicator |

© - All Rights Reserved by Vinayak Equipment